HengMu Pellet Machine Introduction

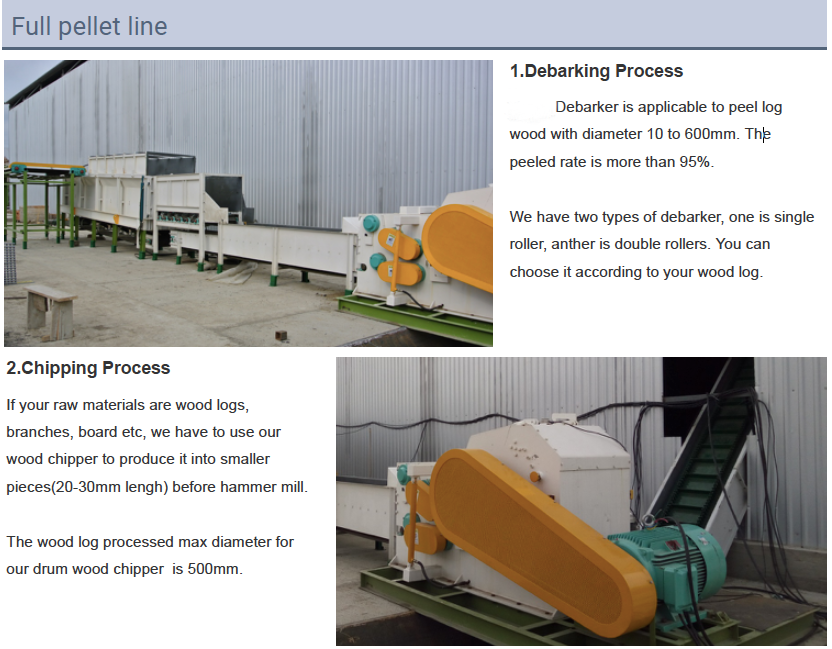

Our pellet machine offers all the benefits of both a flat die pellet machine and a horizontal ring die pellet mill machine. It can work with all kinds of materials, including rice or sunflower husks, crop straws, rubber, ash, cement, branches, peanut and other fruit shells, trunks, branches, bark, and much more.

It uses German alloy steel in its construction for a more secure, reliable build. The die has a fixed and vertical installation that allows easy maintenance and repairs, and the pellet modeling system operates silently and efficiently. This offers a greater life of work along with a more efficient user experience.

Widely used in industry and recommended by experts, the pellet mill can be used in fertilizer, MSW processing, wood processing, power, biomass energy fuel, and chemical plants. For low investment and high profit, the HengMu Pellet Mill is the way to go.

Feature

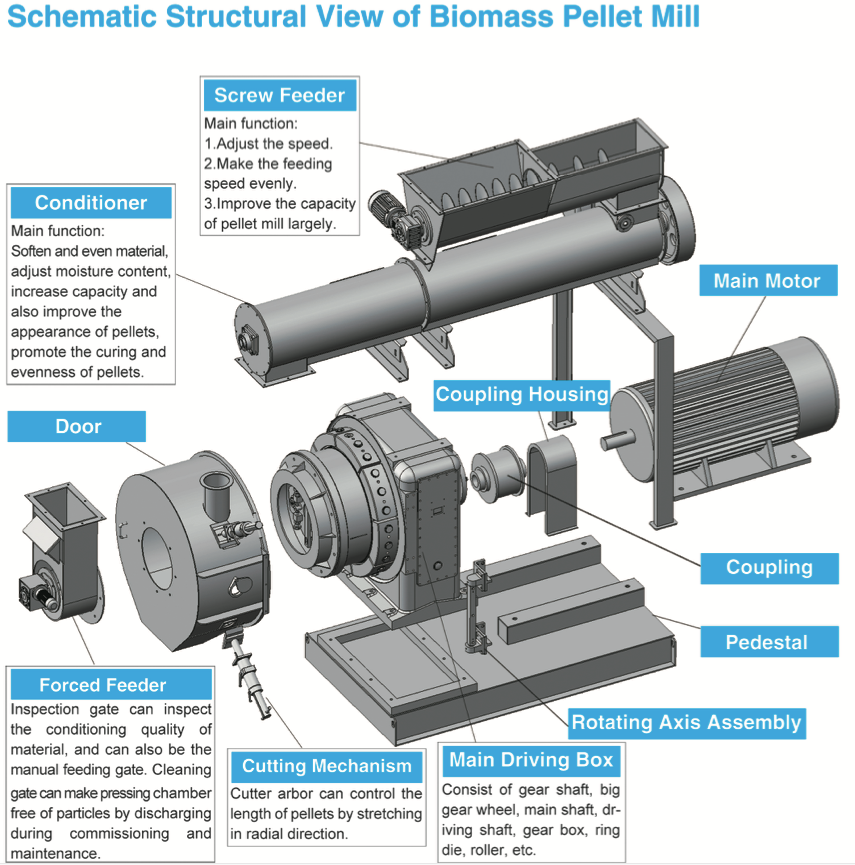

1. Main drive adopts high accurate gear drive,with an output of about 20% higher than belt drive,and the die adopts the quick removing clamps.

2. The drive part of the machine(including motor)optimize the high quality bearings made in Switzerland and Japan,which ensure high efficient and steady driving with low noise.

3. Adopts the frequency-conversion speed ,regulating control to guarantee quality pellet feed.

4. Main spare parts, such as ring dies& rollers etc. are produced strictly according to high quality standard. Ring dies are produced by automatic CNC gun drill machine&coutersinking machine, heat treatment by vacuum furnace, with long service life and making good feeds.

5. The international advanced compensation type flexible coupling is of novel and compact structure,safety,low noise and less trouble.

【Attractive advantages】

1. Non-dust workshop.

2. Siemens motor, Imported SKF/NSK bearing.

3. Equiped with auto cooling and oil adding system.

4. National patent.

5. National patent. Reasonable price.

6. Beautiful pellets with uniform size.

7. Lubrication system consists of automatic lubrication and manual lubrication.

8. Forced feeder: Forced feeding into pelletizing chamber, make pellet mill operate stable and with high efficiency.